Innovative Designs that suit every need

At Ametal we offer a variety of sheet metal work for your unique projects. Our specialisation lies in sheet metal fabrication of Aluminium, Stainless and Mild steel in various thicknesses and we use state of the art CNC (Computer Numerically Controlled) Machines for high precision results and fast turnaround even on high volume orders. Our experts at Ametal ensure that the done is done right the first time to your exact specifications. If you are looking for sheet metal fabrication services, you are at the right place.

ISO Certified

- CAD/CAM

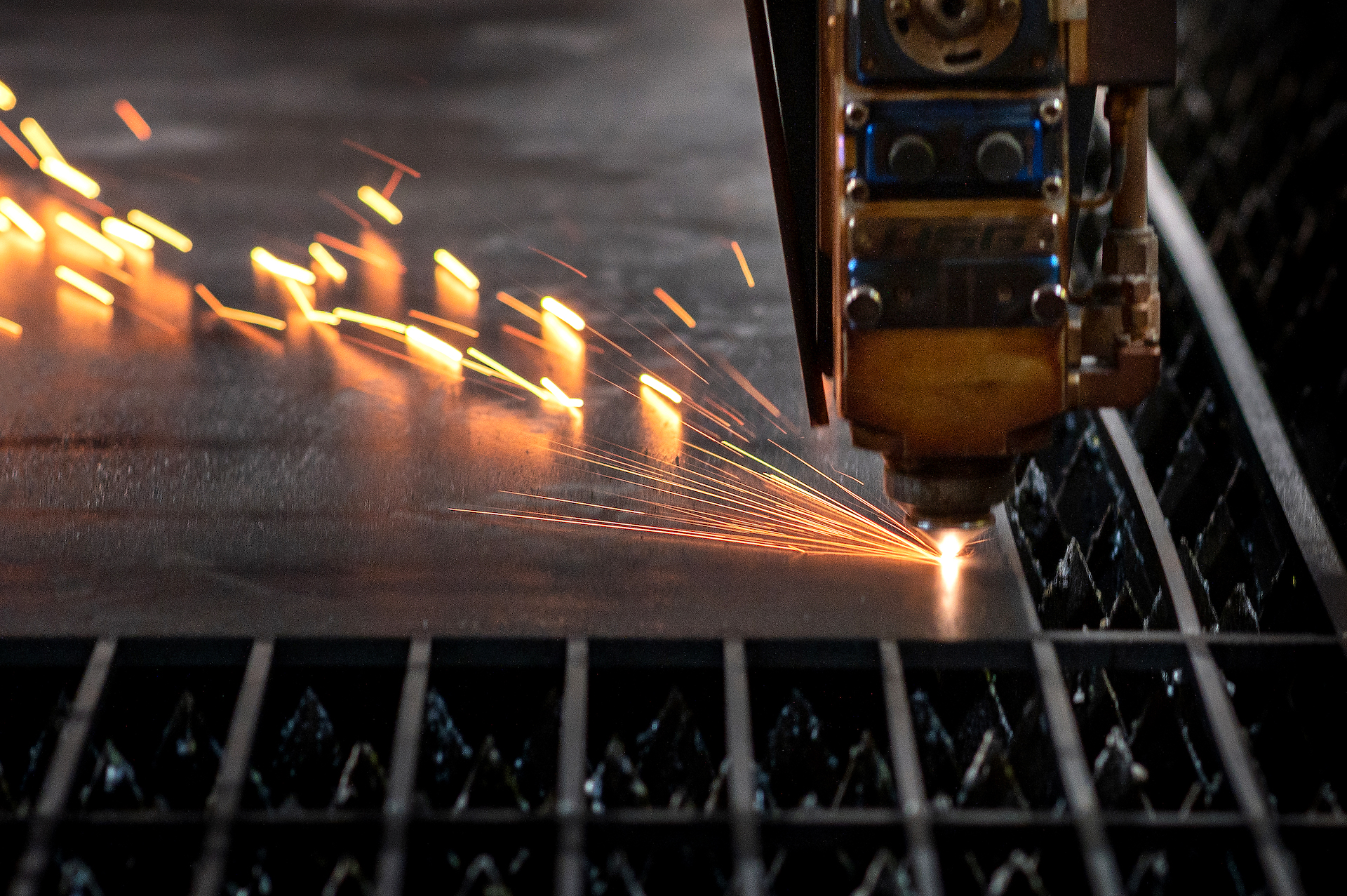

- Laser Cutting

- Laser engraving

- Bending and Forming

- Stamping

- Milling and Turning

- Welding (MIG/TIG)

- Robotic Arm Welding

- Laser Welding

- Powder Coating

- Electrical Control System Wiring

- Machining

We provide a wide range of quality metal fabrication services, within our very own state of the art facilities. These include, laser cutting, shearing, turret punch, press brake, power press, turning & machining, welding and sub assembly.

Our innovative team of engineers together with our highly skilled manufacturing force, can fabricate the most intricate designs with a high quality fit and finish and to exact specifications. Our strength lies in our ability to offer customised products in a short turn-around time.

We use highly advanced Radan CAD/CAM software to innovate new prototypes, improve on existing designs and to optimise our manufacturing process to high precision and time efficiency.

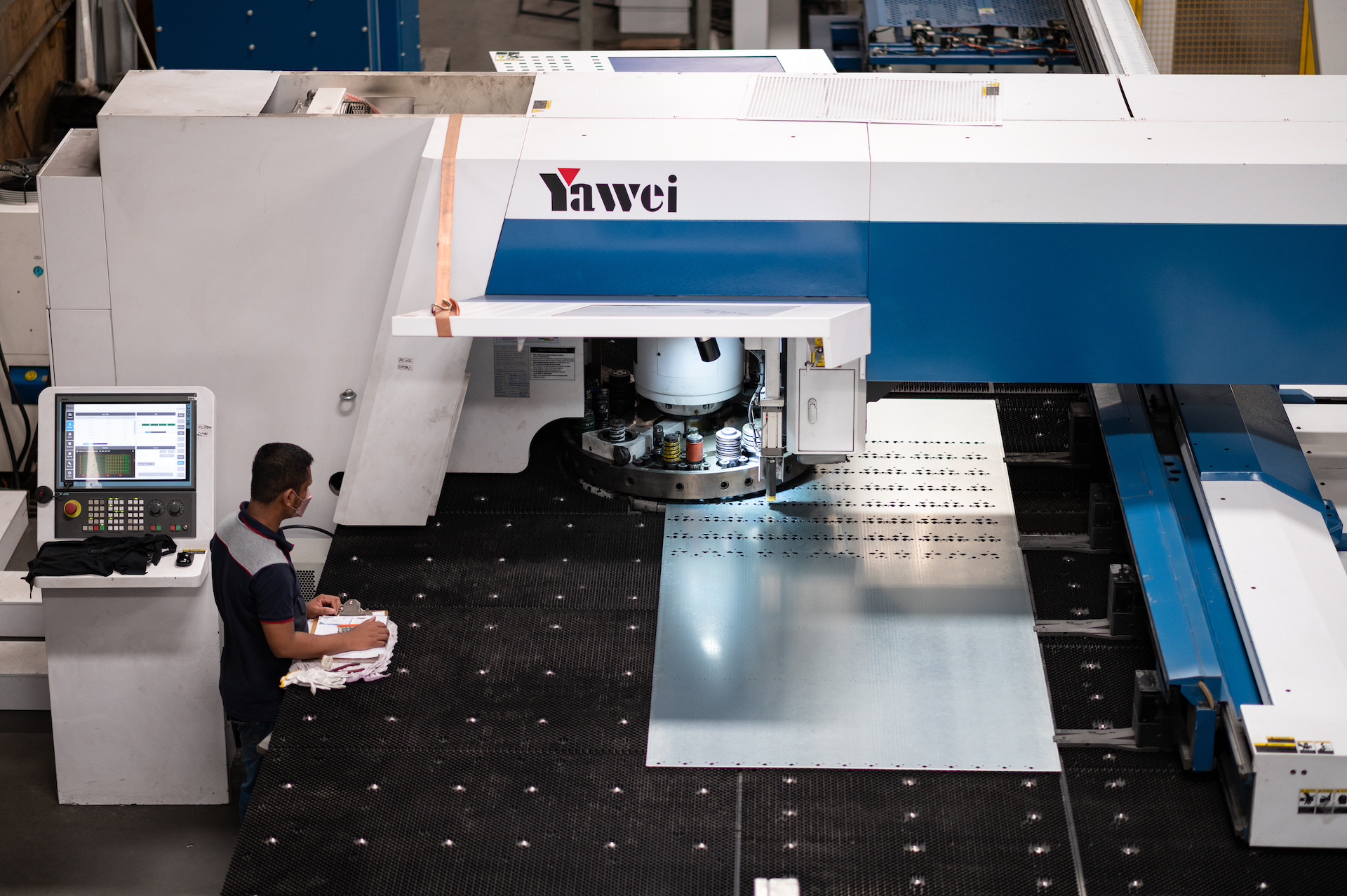

For high precision & fast turnaround turret punching we use CAD designs fed to a combination laser/punching CNC machine. We can punch, engrave and even form to customers requirements.

Ametal CNC precise machine cutting services give anyone the ability to create custom parts from a variety of materials with complex, intricate designs that are impossible to do by hand.

We can create custom parts, tooling or whole finished products from raw materials using a precise machining process by employing CAD design fed to heavy duty CNC machines.

We work with precision CNC pulse mig welding and manual tig, mig and spot welding as well as provide Laser Welding. Our experienced welders ensure high durability and structural integrity of the product.

Ametal specialises in various materials such as Aluminium, Stainless Steel and Mild steel and can perform welding in all three. Once the items are welded we also can offer the services of Powder coating and Polishing.

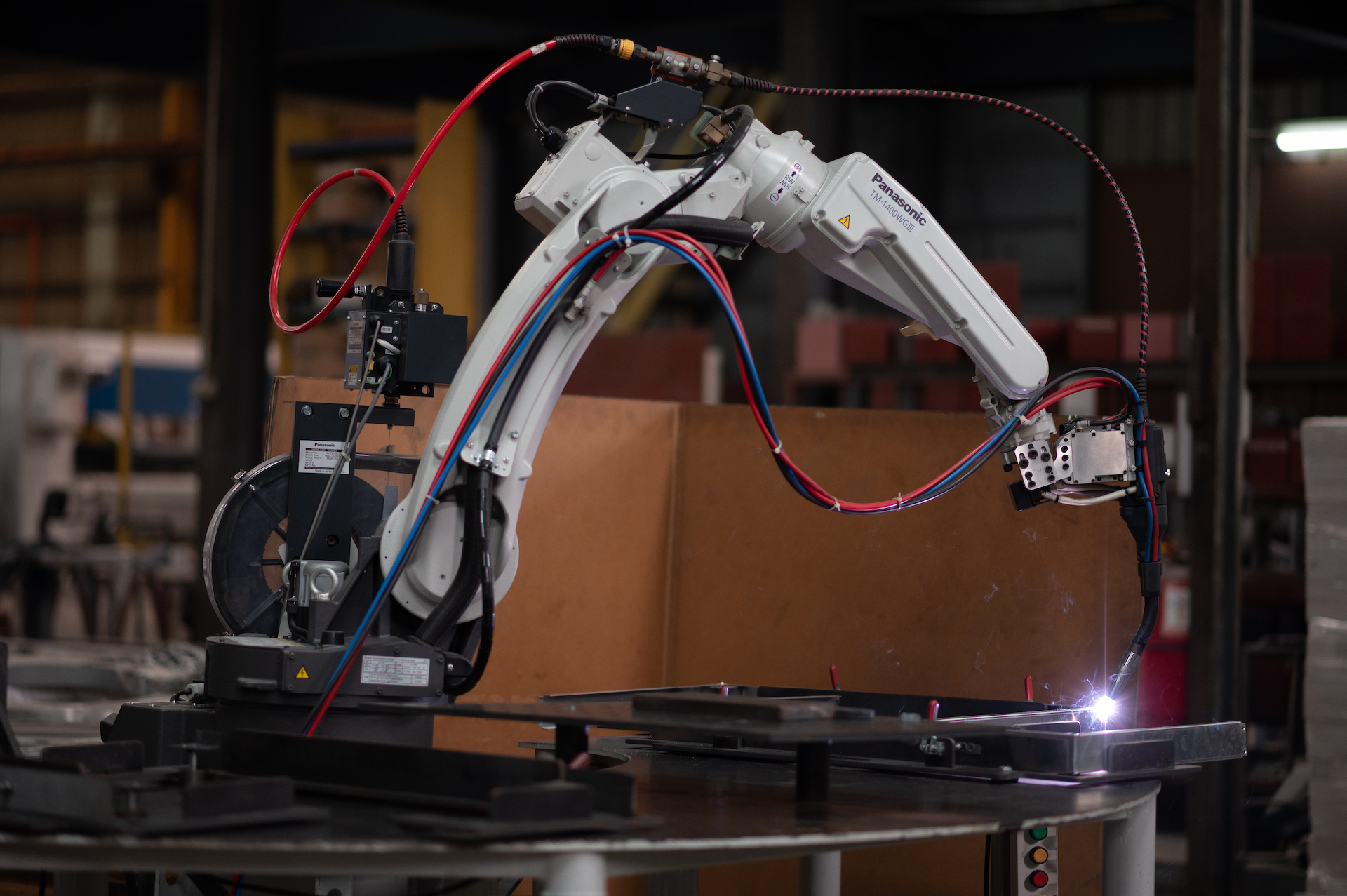

Welding with robots can deliver faster cycle times and consistent quality over manual welding. Ametal uses the high performance Japanese Panasonic TA 14 robotic welding unit.

Automation solutions for bending accelerate the workflows, increase the manufacturing quality, and utilise the maximum potential of the integrated bending systems. It is a CNC manufacturing process where the variables of human operator and manual machinery are completely eliminated, resulting in lowered costs, increased productivity and quality finishes.

Shearing is a metal fabrication process that’s used to trim and remove unwanted material from sheet metal. It involves the use of a machine or tool, such as a bench shear, to slice through sheet metal with extreme precision

We use the CNC milling process to produce both simple and complex shapes, from rings, necklaces, and key holders to automotive and aerospace parts with complex geometries, such as engine components.

Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes.

We provide high quality powder coating using high quality materials, ensuring durability and perfectly smooth surface, as well as a wide palette of colors for the client to choose from.

The quality of control panel layout and wiring is an essential part of design & construction. The goal is to produce a panel that is logically arranged and easy to maintain for the life of the control panel.Each control panel is built using the proper wire size and wire colour to ensure safety, quality, and functionality.